GxP

GxP is a collection of good practice guidelines that span many different fields and activities. In the acronym, GxP, “g” stands for “good,'' “P” is for practice, and the “x” is a variable symbol for the specific descriptor of Good Practice.

The concept of GxP requirements was established by the United States Food and Drug Administration to ensure the safety, efficacy, and proper use of regulated products (e.g., pharmaceuticals, medical devices, cosmetics, food). GxP standards give regulated industries systems and processes to help deliver manufactured products that are safe and fit for use by establishing strict quality standards throughout the entire production process and supply chain. While GxP guidelines are similar from country to country, each has its own regulating body and sometimes different rules.

Purpose of GxP

The purpose of GxP is to protect consumers by guiding products, research, and projects in regulated industries. It is used to enforce rules that require organizations in these industries to:

- Adhere to specific and secure manufacturing processes, storage, and distribution procedures

- Ensure safe clinical trials involving human subjects

- Meet strict research standards for non-clinical laboratory trials

GxP Examples

Common good practices that are included under the GxP umbrella include:

- GAP—Good Auditing Practice

- GCP—Good Clinical Practice

- GDP—Good Distribution Practice

- GLP—Good Laboratory Practice

- GMP—Good Manufacturing Practice

- GRP—Good Regulatory Practice

- GRP—Good Review Practice

- GSP—Good Safety Practice

- GSP—Good Storage Practice

- GVP—Good Pharmacovigilance Practice

Who Is Impacted by GxP?

The range of who is impacted by GxP is broad. It covers products, projects, or research that could put people’s safety at risk, such as food and agriculture, pharmaceuticals, medical devices, and cosmetics. GxP impacts these organizations as well as any other companies that work within regulated industries.

Following are a few ways in which GxP impacts these industries.

- Food and Agriculture

Good practices for storing, handling, and manufacturing food products provide safety guidelines for various food and agricultural products. In the United States, GxP for food and agriculture are found in the Food Safety Modernization Act (FSMA) of 2011 and enforced by the US Department of Agriculture (USDA). - Pharmaceutical

The pharmaceutical industry is impacted by a number of GxP, including good clinical practices (GCP), good laboratory practices (GMP), and good manufacturing practices (GMP), good storage practice (GSP), good distribution practice (GDP), and good pharmacovigilance practice (GVP). Pharmaceutical GxP is overseen by the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe. - Medical Devices

Like the pharmaceutical industry, the medical device industry must comply with a number of GxP. These include GCP, GMP, and GLP. The FDA and the EMA also enforce regulations and review validation of medical device companies’ compliance. - Cosmetics

The cosmetics industry must also comply with different GxP. It is regulated by the Food, Drug, and Cosmetics Act in the United States as well as by restrictions in individual states (e.g., California with Proposition 65). In the European Union, the cosmetics industry must comply with Regulation (EC) No 1223/2009. The Cosmetic Regulations define Canada’s rules for the cosmetics industry.

GxP Readiness

Six core components of GxP readiness are:

- 1. Documentation

- 2. Equipment

- 3. Procedures and processes

- 4. People

- 5. Environment, health, and safety

- 6. Information security and validation

Documentation

To meet the primary GxP requirements, traceability and accountability, robust documentation is required. Considerations for GxP-related documentation are as follows.

- Is there an existing documentation control system?

- Is there a dedicated physical or electronic repository for the storage of active and archived documents?

- Are systems in place for system and data backup and recovery?

- Does the document repository have controlled access as well as policies and processes to guarantee the security of all data and documentation?

- Do dedicated personnel oversee the maintenance and monitoring of the document repository?

- Is there an audit trail to record all changes to documents, with previous versions replaced and stored?

- Is there a Standard Operating Procedure (SOP) for the storage, review, retention, and archiving of documents?

Equipment

Equipment used to produce, store, and transport products must be at a state and quality to guarantee the integrity of the product that is delivered to consumers. To ensure that equipment meets GxP standards, consider the following.

- Is there an equipment inventory, including maintenance records, instructions, and operation manuals?

- Are there documented processes for validating and qualifying equipment?

- Have tolerance limits been established for equipment performance and acceptable lifetime usage?

- Is the equipment’s health continually monitored?

- Are there documented processes for replacing equipment or assets that fail to meet requirements?

- Are there schedules for equipment calibration and maintenance?

- Are logs kept to record relevant information from maintenance and calibration events, including time, date, personnel, and findings?

- Are the records for equipment and assets’ calibration and maintenance securely stored and traceable?

Procedures

Standardized, documented processes are a critical part of GxP. When considering procedures related to GxP, the following are important to note.

- Is there an overarching SOP that directs how other SOPs should be drafted, revised, distributed, controlled, and archived?

- Are all live SOPs centrally located and easily accessible?

- Are SOPs available in their relevant business locations?

- Is there a process for regular reviews of SOPs to ensure that they are up-to-date, compliant, and meeting requirements?

- Is there a process for documenting any deviations from SOPs as well as any corrective and preventative actions (CAPAs)?

The Team

People are a significant part of GxP, as they are at the crux of its successful execution. GxP considerations related to the team include the following.

- Have staff been properly trained to perform the functions and activities of their roles?

- Are all consultants, contractors, suppliers, vendors, and other third parties properly certified, trained, and approved for their roles?

- Is training available for the relevant SOP—for the team overall and specific roles?

- Are there documented training matrixes and plans in place for each role—internal and external?

- Are training status and results recorded?

- Are there regular assessments of employees’ competency?

- Is the organizational chart accurate and updated regularly?

- Does the business have a quality oversight function or department?

- Can employees quickly and easily raise issues, incidents, or concerns to the quality department?

Environment, Health, and Safety (EHS)

A safe, efficient working space is another key factor in GxP compliance. The following should be taken into account to ensure proper EHS measures are in place.

- Are offices, warehouses, manufacturing sites, and other facilities clean, safe, and properly maintained?

- Are operational environmental controls in place?

- Are operational environmental controls regularly audited?

- Do all staff have access to the safety equipment and Personal Protective Equipment (PPE) required for their roles?

- Are there documented cleaning, sanitation, and waste disposal SOPs?

- Is there a dedicated, properly maintained space for documents, equipment, and assets?

- Are spaces for working with and storing documents and equipment clean, safe, and maintained properly?

Information Security and Validation

Following are considerations for implementing and validating information security measures related to GxP.

- Do all computer systems have individual, unique, and strong user IDs and passwords?

- Is there a documented and validated information security policy?

- Are backup systems and processes in place to prevent data loss and facilitate recovery?

- Is there a disaster recovery or business continuity plan in place to respond to IT disruption?

- Are all computer system changes, maintenance actions, errors, and repairs recorded?

- Has software used to support operations been validated and approved for use?

GxP Compliance

GxP compliance requires adhering to standards set forth in the collection of regulations. Agencies and government bodies handle enforcement of GxP regulations through certification requirements, inspections, and audits. GxP compliance requirements are used to protect consumers of products manufactured by companies in highly regulated industries.

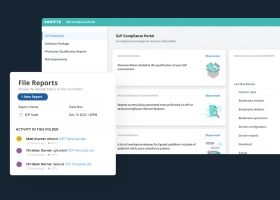

GxP Compliance Software

Software must meet GxP requirements if it is to be used in a GxP-compliant environment or if it is connected to GxP validated instrumentation. Software used in a GxP environment must meet standards set forth in a number of regulations, including CFR21 Part 11, good laboratory practices (GLP), good manufacturing practices (GMP), and good clinical practice (GCP). Note that CFR21 Part 11 compliance is necessary if results from the software are sent electronically directly to the FDA or regulatory bodies as part of submissions.

Among the requirements set forth for GxP compliance software are:

- Audit trails are saved to durable media that logs all activity from the time a record is created until it is finalized.

- Audit trails must have the date-and-time stamp for any change, the description of the change, the reason for the change, and the name of the person making that change.

- Forward compatibility is built into all files that are generated.

- Records both the old value and the new value for a given parameter must be saved so as not to obscure previous values.

- Specific user accounts should be assigned to anyone who has access.

- Tamper protection must be applied to all records, including audit trail records.

GxP compliance software has many benefits, including:

- Creating high-performance products with consistent quality

- Ensuring knowledge is retained

- Maintaining evidence of adherence to compliance requirements for regulated products

- Providing accountability for regulated activity across an organization

- Reducing the risk of product failure or safety-related issues

The 5 Ps of GxP

The five Ps of GxP summarize the core principles.

1. People

- Certify or approve third parties, such as suppliers and contractors.

- Clearly define roles and responsibilities.

- Develop and publish a general quality policy or mission statement.

- Enable validated sanitary practices for employees and equipment to prevent contamination.

- Enforce good hygiene policies.

- Ensure that all procedures are followed.

- Have clear roles and responsibilities.

- Provide a system for individual employees to raise potential quality issues.

- Review training methods.

- Train employees and assess their work.

- Value the work done by highly-skilled employees.

2. Procedures

- Create standard SOPs for critical parts of the process—and review them regularly.

- Document and record all procedures, including critical processes.

- Ensure that all processing excursions or deviations from an SOP are fully investigated, reported, and corrective actions recorded.

- Make all SOPs easily accessible.

3. Products and Primary (Raw) Materials

- Detail specifications for raw materials, components, intermediate and finished products.

- Document the complete master formula.

- Follow approved processes for manufacturing, packing, testing, sampling, status control, stability testing, and records.

4. Premises and Equipment

- Design space and select equipment that can be effectively cleaned for cross-contamination prevention.

- Document processes to qualify, inventory, maintain, monitor, calibrate, clean, replace, and quarantine equipment.

- Enforce safety processes.

- Have procedures, schedules, and records for validation and calibration.

- Maintain and review records of environmental conditions at production and storage facilities.

- Monitor and control processing and warehousing environments.

- Provide staff with necessary personal protective equipment.

- Validate processes.

5. Processes

- Clearly define and document processes.

- Include robust change control procedures.

- Identify critical steps.

- Implement and document change control systems (e.g., equipment, software, utility, documentation, processes).

- Validate processes as well as equipment, software, and utilities that support manufacturing.

GxP Regulations

Three key areas covered by GxP regulations are:

1. Accountability

ISO 9001 Accountability— Identifying every individual’s contribution involved in the development process.

Allows regulators to hold relevant parties responsible for any issues that may arise. This requires the ability to demonstrate what each person has contributed to a product or project and when it was contributed.

To meet accountability requirements, effective, efficient, and accessible documentation is critical. For a product or study, various contributions in parts or whole must be collected and organized. Everything must be documented, including who contributed what and the impact of those contributions as well as every step of the manufacturing process.

2. Traceability

ISO 9001 Traceability – Ensuring that product development history can be reverse-engineered.

Provides the documentation and related records to reconstruct the entire history of a product or project’s creation, making it possible to track the origins and verify every procedure it went through while it was being manufactured. To be compliant, organizations need to document and log every action made by every employee in the development or production of a product or project.

3. Data Integrity

ISO 9001 Integrity of Data – Ensuring data reliability.

GxP data integrity standards ensure the veracity of documentation. For GxP purposes, data collection processes should follow the ALCOA rule—attributable, legible, contemporaneously recorded, original or a true copy, and accurate.

GxP Guidelines for Safe, High-Quality Products and Outcomes

Understanding, implementing, and maintaining GxP standards is an effective way to provide safe products to customers and instill confidence in an organization. There are many ways to meet GxP requirements, but many companies leverage technology to streamline processes, improve security, and enhance data quality. Regardless of how it is adhered to, GxP compliance leads to better products and project outcomes.

Egnyte has experts ready to answer your questions. For more than a decade, Egnyte has helped more than 16,000 customers with millions of customers worldwide.

Last Updated: 7th November, 2021